What Is Supplier Information Management: An Essential Guide

Click on the product you’re interested in learning about and get an interactive walkthrough.

Imagine this: one of your critical suppliers can’t fulfill your most recent order size due to supply chain disruptions. The order is supposed to be delivered in a week, and if you don’t have the full order size, your ability to sell your product will be hindered.

How do you even begin to solve this issue?

Procurement teams often turn to their supplier database to search for a backup vendor but how do you know which supplier can best handle this last-minute order? Do you have a backup supplier in this case? Can you even access accurate supplier data to make such a quick decision?

This is where Supplier Information Management (SIM) comes in. SIM is an essential part of any procurement or supply chain process, and it’s important to implement best practices to ensure SIM processes are as effective as possible.

What Is Supplier Information Management?

Supplier information management is the process of managing and tracking supplier data. This can include anything from contact information to performance data to delivery times. The goal of SIM is twofold:

- Make it easy to find the supplier information you need when you need it.

- Make sure that all that information is accurate and up-to-date.

Accomplishing this can be challenging, given that supplier data can come from various sources, like ERP systems, spreadsheets, and emails, and is often entered by various employees, like purchasing agents, engineers, and suppliers.

However, with the right tools and processes, SIM can be invaluable for improving supplier relationships, supply chain efficiency, and communication.

The Benefits of Supplier Information Management

There are several benefits to implementing a sound supplier information management process. The most obvious is that SIM can help you make better, more informed decisions about your suppliers.

Having streamlined data management processes for supplier health, performance, and capacity can help you identify and avoid potential risks, and ensure you’re sourcing from the most qualified suppliers. Additional benefits include:

- Enhanced Compliance: Ensuring all suppliers meet regulatory and industry standards can be more easily managed and tracked with a robust SIM process, reducing the risk of non-compliance penalties.

- Increased Efficiency: Automated data collection and management processes reduce manual errors and the time required for data entry, allowing teams to focus on strategic activities.

- Improved Collaboration: Better data transparency fosters stronger collaboration and communication between procurement teams and suppliers, leading to more effective partnerships.

- Risk Mitigation: Continuous monitoring and analysis of supplier data help in early identification of potential issues, allowing for proactive risk management and contingency planning.

- Better Strategic Planning: Comprehensive and accurate supplier information supports long-term planning and strategic sourcing decisions, aligning supplier capabilities with organizational goals.

- Sustainability and Ethical Sourcing: A robust SIM system can track and ensure adherence to sustainability and ethical sourcing practices, enhancing the organization’s reputation and aligning with corporate social responsibility goals.

Supplier information management can also have a positive impact on your bottom line. Procurement teams can better manage supplier data, resulting in standardized procurement processes, improved supplier relationships, and reduced time and money wasted on sourcing mistakes.

See the Platform

Not quite ready to talk to someone but want to see what SupplierGateway platform have to offer? Click on the product you’re interested in learning about and get an interactive walkthrough.

Best Practices for Supplier Information Management

There are a few best practices that you should keep in mind when it comes to supplier information management:

- Centralize Supplier Information: Having a master database ensures supplier data entries only exist in one place and only need to be updated in one area. Centralized data also allows for easy access and updates to maintain accuracy and relevancy.

- Establish Standardized Processes: Collecting and managing supplier information according to a standardized framework ensures that everyone involved in the process is on the same page and that data is collected consistently across all suppliers.

- Create Data-Based Procedures: Evaluate and manage supplier risk based on supplier data to identify and mitigate any risks posed by your suppliers and help your organization make more intelligent decisions.

Implementing these best practices will not only streamline supplier management but also enhance overall operational efficiency. By ensuring data accuracy and consistency, organizations can foster stronger supplier relationships and drive better business outcomes.

Common Challenges With Supplier Information Management

There are several common challenges you may face when dealing with supplier information management. One of the most significant is the sheer number of suppliers you need to onboard and manage. With hundreds or even thousands of suppliers, it’s easy to lose track of essential details.

The easiest way to overcome this challenge is to identify suppliers that are critical to the success of your business and ensure the data for those suppliers is monitored. Learn more about how to identify your critical suppliers here.

Another challenge is the manual process involved in tracking supplier data. Manual data entry is tedious, time-consuming, and outdated. This process becomes even more difficult when dealing with global suppliers who operate in multiple countries with different regulations. You can avoid the challenge of manually tracking supplier data in two ways:

- Stop doing manual data collection. Instead, establish a supplier onboarding portal that allows suppliers to enter and update their data at their convenience.

- Monitoring your supplier data accuracy with automated alerts. The alerts should notify you and your supplier when documents like certifications and contracts are due to expire and need to be renewed.

Finally, many organizations lack a standardized system for collecting and managing supplier information. This can lead to inconsistent communication between teams and departments. It can also create difficulties in tracking key performance indicators (KPIs) such as compliance and performance metrics.

Eliminating this problem is simple — use one unified supplier information management software as your source of truth for supplier information.

Subscribe

Get thought leadership, upcoming events, SupplierGateway product updates, and more directly in your inbox.

How to Choose the Right Solution for Your Needs

A solid understanding of supplier information management features and capabilities can help you decide which solution is the best fit for your needs. It’s important to choose a solution that has a user-friendly interface and provides the tools, insights, and analytics needed to make strategic decisions.

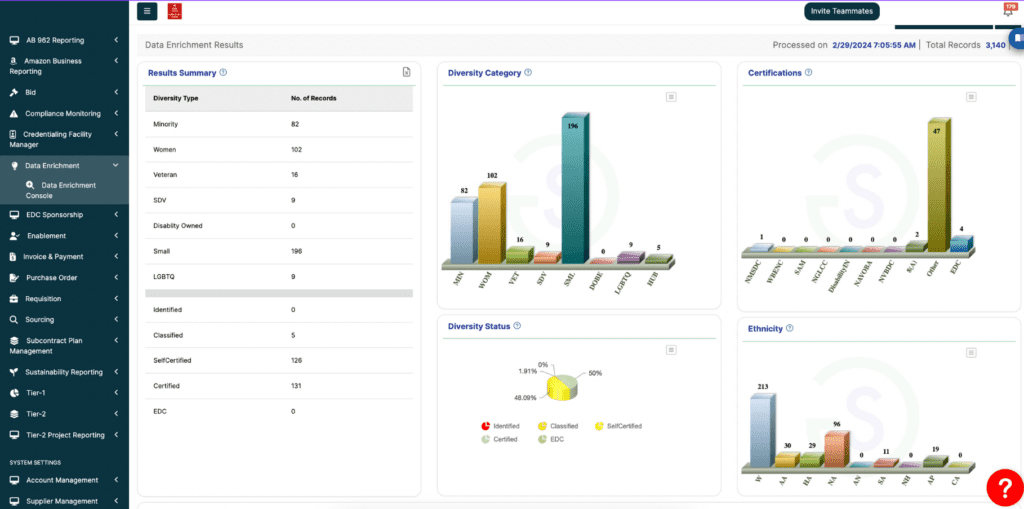

Intuitive, strategically organized dashboards with all of your critical supplier information.

The Enterprise Supplier Data Management Platform from SupplierGateway, for example, offers several key features, including:

- Streamline supplier onboarding

- Monitoring supplier risk

- Compliance management

- KPI tracking

- Diversification strategies to meet DEI goals

- Communication tools to enhance supplier relationships

Our platform also includes supplier portfolio dashboards to help you quickly source and choose the perfect vendors. Additionally, it enables stakeholders to share data across departments in a secure environment.

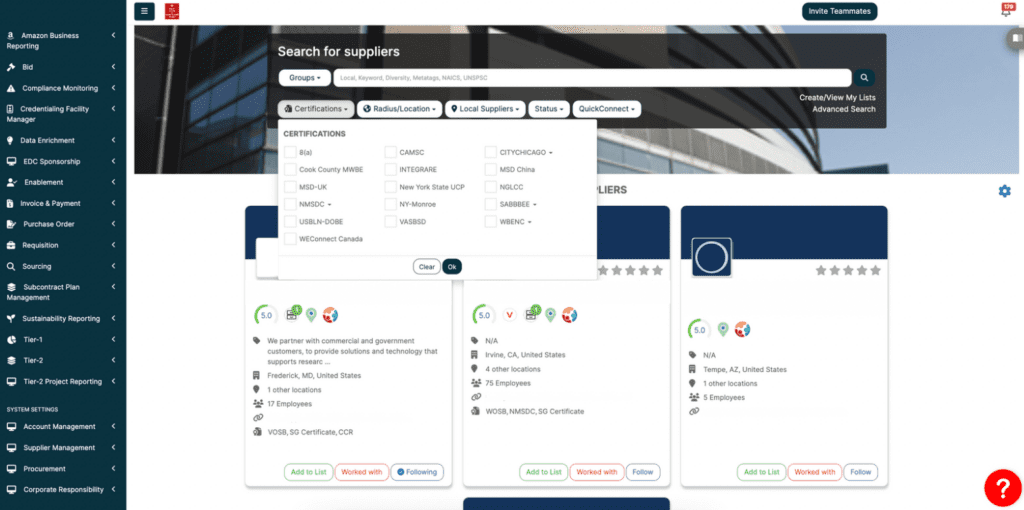

Search across specific metrics, browse profiles, and communicate in the Search Portal.

When evaluating supplier information management software, ask specific questions and get references from colleagues in your industry. Make sure the platform you choose can scale with your business, works with your ERP systems, and helps you strengthen supplier relationships.

5 Tips to Get the Most Out of Your Supplier Information Management

If you want to get the most out of your supplier information management, here are five tips you should follow.

1. Establish a Standardized, Self-Service Supplier Onboarding Process

Establishing a standardized onboarding process will boost accuracy and speed up your onboarding process. Utilizing a self-service portal that suppliers can access anytime will also help eliminate time spent hunting down supplier information.

2. Leverage Supplier Risk Data

Supplier risk data can help you identify suppliers with low compliance scores or poor performance records. Using supplier risk data can help you make more informed decisions when selecting suppliers and ensure that they meet your company’s requirements.

3. Monitor Supplier Performance KPI Metrics

Supplier performance KPI metrics can help ensure that suppliers meet their contractual obligations, such as timelines and deliverables. Tracking performance metrics will also help you identify areas where there may be issues or potential delays in order fulfillment.

4. Keep Your Supplier Data Up-To-Date

Ensure that information about your suppliers is up-to-date by setting a regular schedule for updating records. Doing so will make it easier to communicate with suppliers when necessary and guarantee the accuracy of supplier data company-wide.

5. Leverage Third-Party Services

Leveraging third-party services such as SupplierGateway’s Enterprise Supplier Data Management Platform can automate parts of your supplier management processes and ensure that internal stakeholders have access to accurate data in one central repository. Your company will save time, money, and resources while increasing compliance and reducing risk.

Manage Supplier Information with SupplierGateway

So, what is good Supplier Information Management (SIM)? And how can your business ensure it is doing everything to get the most out of its supplier data?

Good supplier information management starts with understanding the data your suppliers are providing. This includes contact information, order history, shipping information, and more. When you understand your supplier data, you can implement processes that will help you make the most of it.

There are several best practices that your business can implement to improve its supplier information management. Some of these best practices include developing standard operating procedures for handling supplier data, creating a “master data” for all supplier information, and using supplier data to improve your business intelligence.

Utilizing a data management platform like SupplierGateway’s Enterprise Supplier Data Management Platform helps you quickly onboard suppliers, keep supplier data updated, ensure supplier compliance, and much more.

Find Out More

When you’re ready to start making your supplier data work for you, reach out and schedule your demo.