Key Takeaways

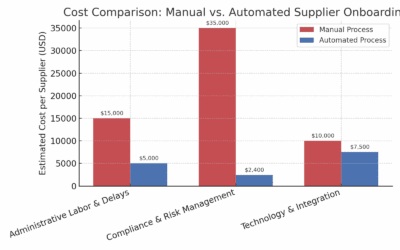

- Manual onboarding is expensive – It can cost more than $35,000 per supplier compared to less than $2,500 with automation.

- Early risk assessment is critical – More than 80% of organizations detect supplier risks only after onboarding begins, making issues more costly to fix.

- Centralized, accurate supplier data is essential – A single source of truth improves compliance, performance tracking, and communication.

- Clear contracts and policies prevent disputes – Well-defined expectations from the outset protect relationships and reduce operational friction.

- Ongoing performance monitoring safeguards relationships – Regular KPI tracking ensures issues are addressed before they disrupt operations.

Why Vendor Onboarding Matters More Than Ever

Vendor onboarding is where a supplier shifts from “potential partner” to “active contributor.” It’s the stage when expectations are set, compliance is confirmed, and the operational foundation is laid for what could become a long-term relationship. Done right, onboarding accelerates productivity, reduces risk, and fosters collaboration. Done wrong, it leads to inefficiency, compliance issues, and damaged relationships.

The stakes are even higher in 2025. Procurement teams face:

- Tighter budgets that demand faster, more efficient onboarding

- More complex compliance rules that increase the cost of errors

- Greater supply chain volatility that exposes weak onboarding processes

Relying on outdated, manual workflows can make these challenges worse, slowing supplier readiness, introducing data errors, and leaving teams in the dark about where suppliers stand in the process.

Laying the Groundwork for Success

Strong onboarding starts before the first form is sent. Leading organizations create standardized processes that guide every supplier through the same evaluation and setup steps. These processes are:

- Aligned with sourcing strategy so each supplier supports the organization’s broader goals

- Built for compliance to meet industry, legal, and internal policy requirements

- Tracked centrally so progress is visible to all stakeholders, from procurement to finance

When everyone works from the same playbook and can see the same information, onboarding moves faster and with fewer surprises.

Identifying and Managing Risk Early

One of the costliest mistakes in onboarding is waiting until after a contract is signed to address supplier risk. Early risk assessment should evaluate:

- Qualifications – Can the supplier meet your standards?

- Capabilities – Do they have the infrastructure to deliver?

- Financial stability – Can they sustain the relationship long term?

- Reputation – Will working with them reflect well on your brand?

- Regulatory compliance – Are they aligned with relevant laws and requirements?

Combining self-reported supplier data with third-party verification creates a fuller, more reliable picture. This approach prevents costly disruptions that often surface when risks are detected too late.

Policies That Support Consistency and Fairness

Vendor management policies act as the rules of engagement for onboarding. They ensure suppliers are evaluated consistently and fairly, and they make expectations clear from the start. A good policy addresses:

- Selection criteria that define what makes a supplier a fit

- Data collection methods that prioritize direct-from-supplier accuracy

- Communication protocols for ongoing collaboration and dispute resolution

When suppliers know exactly what’s required of them and buyers have a clear, repeatable process, both sides benefit from fewer delays and less confusion.

Contracts as Operational Blueprints

Contracts do more than protect your organization legally—they define the day-to-day expectations of the relationship. The most effective contracts include:

- Payment terms that are clear and agreed upon

- KPIs and quality standards that set measurable performance benchmarks

- Compliance requirements that align with industry and regulatory needs

- Dispute resolution processes that avoid costly legal conflicts

By documenting and measuring supplier performance against these expectations from the start, organizations create a foundation for accountability and informed decision-making.

Leveraging Automation for Speed and Accuracy

Automation has become a baseline expectation in supplier onboarding. Modern portals allow suppliers to enter their own data, reducing manual errors and speeding the process. Custom workflows ensure that suppliers see only the steps relevant to them, making onboarding more efficient and supplier-friendly.

Beyond onboarding forms, automation can also:

- Streamline documentation by eliminating redundant data entry

- Integrate with ERP/AP systems to keep records consistent across platforms

- Automate invoicing to ensure faster, more accurate payments

These efficiencies free procurement teams to focus on strategic supplier management rather than administrative tasks.

Ongoing Performance Management

Regular KPI reviews ensure that suppliers meet agreed-upon standards and help identify opportunities for improvement.

Periodic performance evaluations, whether quarterly or semi-annual, allow both sides to address challenges early and build on successes. This proactive approach keeps relationships strong and prevents operational disruptions before they happen.