Supplier onboarding is a pivotal step in establishing a productive relationship with a new vendor. It’s where information is exchanged, compliance is verified, and systems are aligned so work can begin. Yet for many organizations, onboarding is also one of the most expensive and time-consuming stages of the supplier lifecycle.

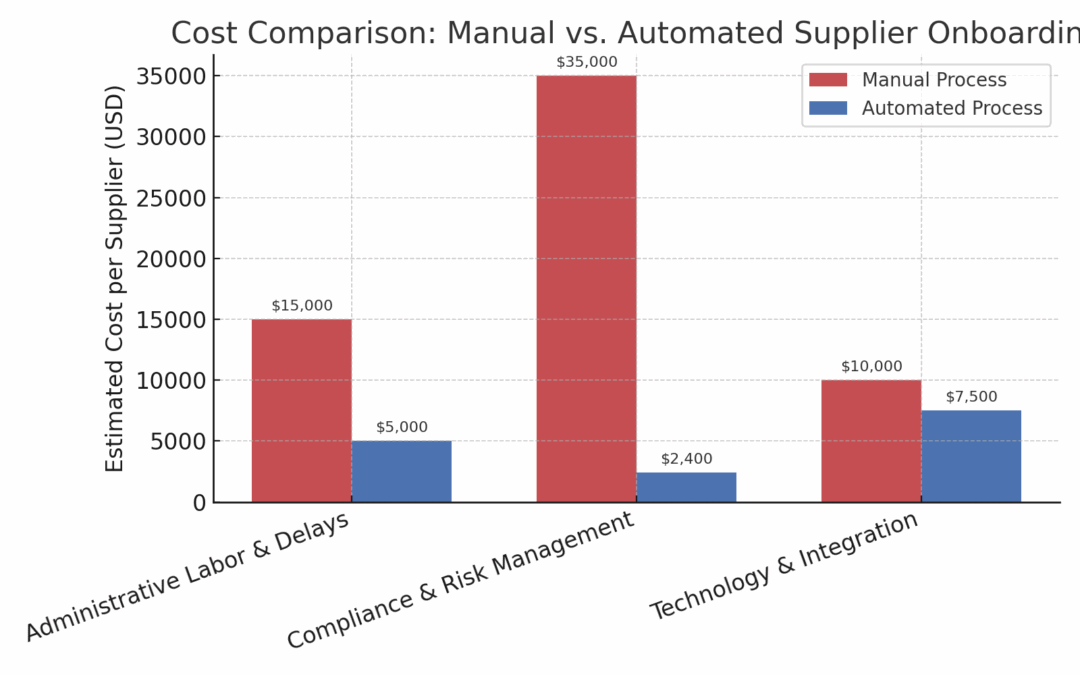

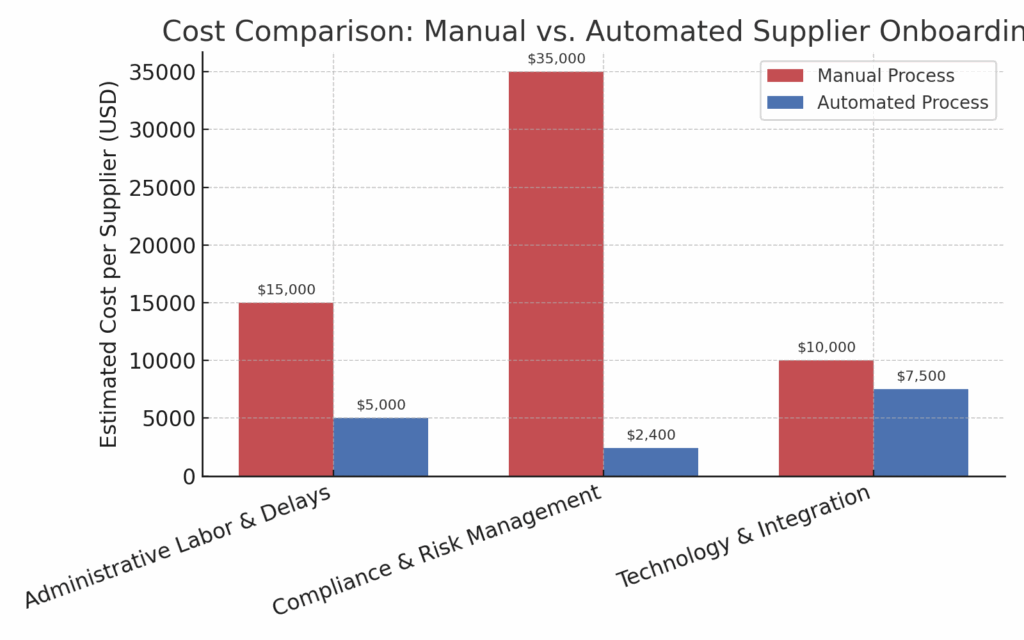

While every organization’s numbers vary, research shows that inefficient onboarding can cost tens of thousands of dollars per supplier, and those costs extend beyond the obvious administrative effort. They fall into three main categories: administrative labor and delays, compliance and risk management, and technology and integration.

1. Administrative Labor and Time Delays

The most visible cost comes from the hours teams spend collecting, reviewing, and correcting supplier information. Manual processes like emails, spreadsheets, and PDFs are slow, error-prone, and often require repeated follow-ups. These tasks can consume days or even weeks of work, tying up procurement, legal, and finance staff who could be focused on higher-value activities.

The real impact extends beyond payroll. When suppliers aren’t fully onboarded, they can’t start work. Every delay pushes back project timelines, product launches, or service rollouts. This not only disrupts operational plans but can also delay revenue generation.

2. Compliance and Risk Management Costs

Verifying compliance with tax laws, regulatory requirements, and internal standards is essential, but it comes with its own set of expenses. Without streamlined processes, these checks require significant staff time and can result in costly mistakes.

The numbers tell a clear story: manual onboarding can cost as much as $35,000 per supplier, while automation can reduce that to around $2,400 (Veridion, 2025). The gap reflects not just the labor savings, but also the cost of avoiding post-onboarding remediation when a compliance issue is caught too late. Fines, contract disputes, and operational shutdowns caused by non-compliance can easily outweigh the original onboarding expense.

3. Technology and Integration Expenses

Many organizations turn to supplier management or onboarding platforms to handle data collection, approvals, and communication. While these tools reduce manual workload, they come with costs for licensing, customization, and integration into existing ERP or procurement systems.

When technology isn’t fully integrated, teams often end up duplicating work; manually re-entering data, managing multiple logins, or reconciling conflicting records. This erodes the return on the software investment and increases the risk of errors. On the other hand, when implemented strategically, automation can lower onboarding costs by up to 25% and cut cycle times by about 50% (Cflow Apps).

Managing the Costs Before They Spiral

The costs of supplier onboarding are unavoidable, but they can be controlled. Organizations that invest in:

- Automation to replace manual data collection

- Integrated compliance checks to catch risks early

- Well-planned technology rollouts

…are seeing measurable reductions in both time and expense. They’re also improving supplier satisfaction, which can have long-term benefits for performance and collaboration.

By addressing these three cost drivers early, procurement teams can shorten onboarding timelines, reduce operational risk, and get more value from every supplier relationship.