Manual onboarding processes can cost your organization millions of dollars, and you may not even realize it.

Key Takeaways:

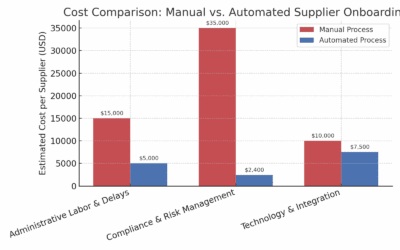

- Manual onboarding is costly – up to $35,000 per supplier when done manually versus a fraction of that with automation.

- Most risk detection happens too late – over 80% of organizations identify supplier risks after onboarding, when fixes are harder and more expensive.

- Poor vetting has financial and compliance consequences – skipping thorough checks can lead to operational delays, lost revenue, and regulatory issues.

- Failure to modernize wastes efficiency gains – automation can halve onboarding timelines and reduce errors, yet many organizations still rely on outdated processes.

While that may seem like clickbait to grab your attention, it actually highlights the significant time and money wasted on risk-laden onboarding processes. These money losses don’t just show up in obvious ways, but in subtle, systemic ways that many organizations overlook.

If onboarding feels slow, expensive, or fraught with surprises, you’re not alone. Below are four common, but often unrecognized risks that can quietly erode efficiency, compliance, and trust and cost a ton of money in the process.

Risk 1: High Hidden Costs of Manual Processes

It’s not just the visible hours spent chasing documents or chasing supplier responses. According to firms like Deloitte, EY, and McKinsey, onboarding can cost up to $35,000 per supplier when done manually, compared to just $2,400 or less when automated. That means every bottleneck, misfiled document, or unchecked form can contribute to mounting operational expense.

Risk 2: Late-Risk Detection

Most companies only spot supplier risks after onboarding is done. That’s the case for more than 80% of organizations, according to recent data from Gartner. By then, it’s often too late—the damage can affect finances, operations, or reputation. Early detection isn’t a luxury; it’s a necessity.

Risk 3: Poor Vetting Can Cost You More Than Money

Neglecting proper vetting isn’t just risky—it’s costly. Companies that overlook supplier risk slow down operations, and in some cases, lose significant revenue or face compliance failures. As one expert puts it: “The cost and risk of selecting poorly vetted suppliers can be greatly minimised by improving your onboarding process.” It’s a reminder that onboarding is your first—and most critical—defense.

Risk 4: Missed Opportunity to Modernize for Efficiency

Organizations that don’t modernize their onboarding process miss out on dramatic gains. According to the Institute of Supply Management, automation can halve onboarding timelines while cutting errors and costs.

If you haven’t reassessed your approach in a while, chances are you’re trading speed, accuracy, and cost savings for outdated methods.

What You Can Do Now

- Run a cost audit: Compare your current onboarding costs against automated benchmarks.

- Shift left on risk: Integrate risk detection before final supplier approval.

- Standardize vetting: Ensure every supplier goes through the same risk and compliance checks.

- Adopt automation: Look into tools that reduce onboarding time by 50% or more.

Final Thought

Costly manual workflows, late risk detection, poor vetting, and missed efficiency opportunities don’t just slow you down; they erode your competitive edge. But recognizing them is the first step toward lasting improvement.

See how automating the onboarding process can cut your onboarding time by 70% or more. Take a product tour or book a call with our team of experts to learn more.